Is Epoxy Resin Food Safe?

Epoxy has many uses in the kitchen. Because it can be both an effective adhesive and a coating material, it has both practical and purely decorative uses. It's strength as an adhesive is second to none, so you may be considering using it to repair broken items in the kitchen. Because it can work equally well with wood, plastic, fiberglass, ceramic or even metal, you can use it to repair almost anything.

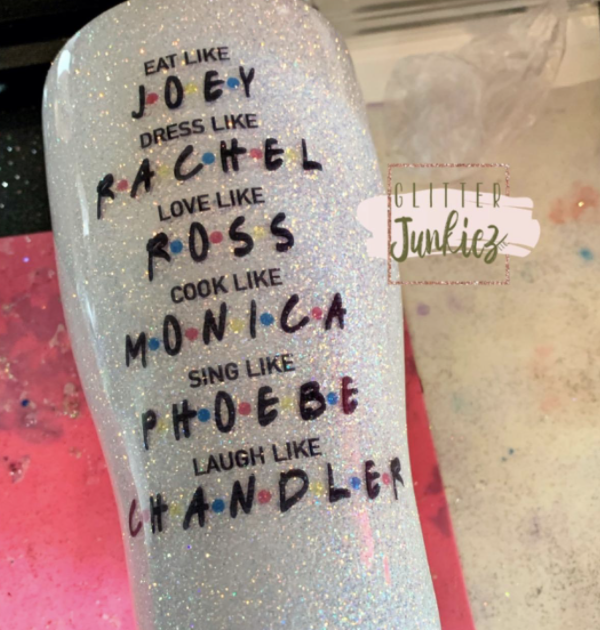

Once it's cured and dried it's crystal clear and very hard, so it has plenty of aesthetic uses as well. Many people like to coat wooden tables, chairs, coasters and counter tops with epoxy. This creates a hard, protective surface that preserves the wood, looks great, and is easy to clean. Even wooden cheeseboards can benefit from a coating of epoxy. Since it adheres to metal, stainless steel tumblers can be given personalized decoration by applying a coat of epoxy and adding decorations before it's completely dried.

With its popularity in the kitchen, it's fair to wonder how safe it is to use epoxy on surfaces that will come into contact with your food. Epoxies, after all, are plastics, and it seems that every day brings a new story on how bad it is to let your food touch plastic.

EPOXY USED IN THIS VIDEO

Is epoxy FDA approved?

The short answer is: kind of. First, understand that not all epoxies are safe for use in the kitchen. A lot of people use epoxy in places that it will never come into contact with food: adhesives in airplanes or cars, a clear coat over an oil painting, a waterproof layer on a wooden boat, and so on. These epoxies will never touch food, and there's no need to make them food safe.

There are FDA approved food grade epoxies though. Notice that they are food grade, not food safe. Epoxies are not sold as finished products. They are separate compounds that you mix together to create the finished product. In order to render any epoxy food safe, you have to cure it properly. So, the FDA isn't going to certify an epoxy as food-safe, because that will depend on you. Food grade epoxies will be food safe when cured correctly.

All epoxies form an inert plastic once cured, but there are plenty of inert plastic products we wouldn't consider food safe. That's because they contain bisphenol-A (BPA), which may be able to leech into our food and cause health problems (the FDA is still researching this) and volatile organic compounds (VOCs), which may also cause health problems. Food grade epoxies have lower amounts of BPA and VOCs than other epoxies.

How to cure epoxies to make them food safe

Even food grade epoxies are not food safe if they aren't cured correctly. Your epoxy should come in two bottles: one bottle of resin and one bottle of hardener. It's usually best to mix and apply your epoxies in a relatively warm space. Mixing will be very difficult if the epoxy is colder than about 75 degrees.

Important Note: Even food grade epoxies are not food safe if they aren't cured correctly.

It's also a good idea to apply epoxy in two coats, a thin seal coat that can be brushed on to seal the wood and prevent air bubbles from rising later, and a thicker coat that is poured on once the seal coat is dry. This is only necessary for porous surfaces like wood.

You need a very clean container for mixing, and accurate measuring tools. Most products will need a one-to-one ratio of resin to hardener, which means that to make your epoxy food safe, you need to use exactly the same amount of resin and harder in the mix. If your measurements are off, the epoxy will never cure completely, and therefore will not be food safe.

Mixing the two together may take a while. The length of time it takes will depend on the specific product, but you must always be careful to mix slowly or you will introduce air bubbles into the mixture. It can take several minutes of continuous mixing before the epoxy is ready to use. You will know that mixing is complete when the epoxy turns from cloudy and opaque to clear with no white streaks remaining.

Be careful to scrape the sides of the container while mixing. If any unmixed resin or hardener remains on the sides of the bucket, when you pour it out it will create uncured wet spots in the epoxy. When you pour the epoxy out, do not scrape the sides or bottom of the bucket to try and get all of the epoxy out. No matter how thoroughly you mixed, there will be small bits of unmixed epoxy there.

Be sure not to leave the bucket unattended. Epoxy is formed by a thermal reaction, and if it's left in the bucket too long it can generate enough heat to begin smoking, and can then very quickly cure inside the bucket.

Make sure that the surface you are applying epoxy to is sanded, clean, and dust free, and always wear gloves when working with epoxy. While it is safe and non-toxic, it is very sticky and it will be difficult to remove if it gets on your skin.

Conclusion

As long as you buy food grade epoxy and cure it properly, it will be safe to use on surfaces that will come into contact with your food. If you have never used epoxy before, these instructions may be overwhelming. It really isn't as difficult as it seems, but even experienced epoxy users can have problems with the cure occasionally. For that reason, if you've never worked with epoxy before, it may be a good idea to do a couple of test batches first. Pick up a two by four or some wood from a hardware store and coat it with epoxy to make sure you have the process figured out before you coat a whole counter top in it. Once you're sure that you can cure the epoxy properly, you're good to go.